UltraBloc Preheater Systems

Home > Products > REFSOURCE Fiber Products > UltraBloc Custom Engineered Panels > UltraBloc Custom Engineered Panels

REFSOURCE UltraBloc Custom Engineered Panels combine the thermal benefits of ceramic fiber with the labor savings of a modular prefabricated design. UltraBloc Panels are produced using various grades of ceramic fiber materials specifically designed to meet a customer's unique application. Using the "spun" process, the fibers yield long, flexible and have high-tensile strength for maximum durability. Temperature grades of fiber used can range up to 3000ºF for the most extreme applications.

UltraBloc Panels are custom engineered per the customer's specific application. Every panel is designed to minimize joints in the ceramic fiber lining and maximize the compression between the fiber layers. This results in yields of densities of a minimum 12 pounds per cubic foot. Another benefit is that the ceramic fiber chosen is based upon temperature limits for each application to insure maximum life and performance.

UltraBloc Features

- Engineered Shape

Custom engineered to customers’ spec by REFSOURCE... including drawings. - Customized Lining

Fibers chosen to match application and maximize life... up to 3000°F applications. - Fortified Design

Compression between layers is maximized, yielding zero joints/gaps with uniform density and minimal shrinkage throughout entire panel. - Proprietary Anchoring

Completely insulated piece anchored by the proprietary REFSOURCE Wall Anchoring System... installation ready!

UltraBloc Benefits

- Highly resistant to mechanical abuse compared to traditional modules

- Minimal shrinkage compared to traditional fiber module installations

- Low thermal conductivity

- High tensile strength

- Thermal shock resistance

- Ready to use

- Requires no curing or drying time

UltraBloc Applications

- • Horizontal Ladle Refracters

-

-

Skirt Horizontal Preheater

Skirt Horizontal Preheater -

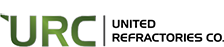

Horizontal Ladle Preheater (mini mill)

Horizontal Ladle Preheater (mini mill) -

Horizontal Ladle Preheater (front)

Horizontal Ladle Preheater (front) -

Horizontal Ladle Preheater (side)

Horizontal Ladle Preheater (side) -

Horizontal Ladle Preheater (integ. mill)

Horizontal Ladle Preheater (integ. mill)

-

Skirt Horizontal Preheater

- • Vertical Ladle Preheaters/Dryers

-

-

Vertical Ladle Dryer

Vertical Ladle Dryer -

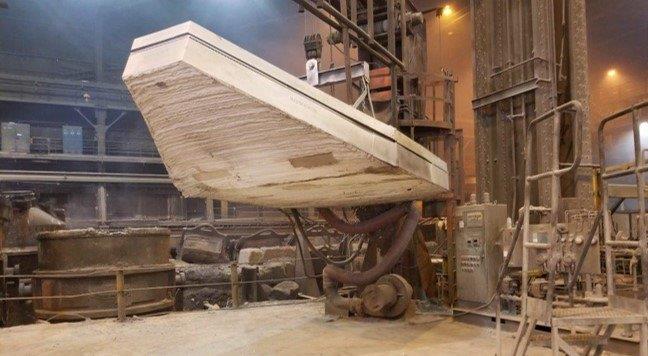

Vertical Ladle Preheater

Vertical Ladle Preheater -

Vertical Ladle Preheater (round)

Vertical Ladle Preheater (round)

-

Vertical Ladle Dryer

- • Vertical Ladle Dyers

- • Vertical Ladle Covers

-

-

Vertical Ladle Cover Hotface (half section)

Vertical Ladle Cover Hotface (half section) -

Vertical Ladle Cover Hotface

Vertical Ladle Cover Hotface -

Vertical Ladle Cover

Vertical Ladle Cover

-

Vertical Ladle Cover Hotface (half section)

- • Tundish Preheaters

-

-

Tundish Cover

Tundish Cover -

Tundish Preheater

Tundish Preheater

-

Tundish Cover

To learn more about our UltraBloc Custom Engineered Panels Solutions contact one of our sales reps and put our 100 years of combined experience to work for you.